-

Innovative orbital

solutionsDécouvrir nos machinesNotre métier repose sur le processus global de travail du tube :

préparation (coupe, chanfrein ou dressage) et soudage orbital.

Notre métier repose sur le processus global de travail du tube :

préparation (coupe, chanfrein ou dressage) et soudage orbital.

Le groupe S.F.E. a été fondé en 2019 après la fusion de trois fabricants d'équipement d'origine (FEO) leaders mondiaux dans le domaine de l'outillage et des machines pour tubes : TAG Pipe Equipment Specialist Ltd (Royaume-Uni), Mathey Dearman Inc (États-Unis) et B&B Pipe and Industrial Tools LLC (États-Unis)..

Récemment, le groupe S.F.E. a finalisé l'acquisition du groupe AXXAIR.

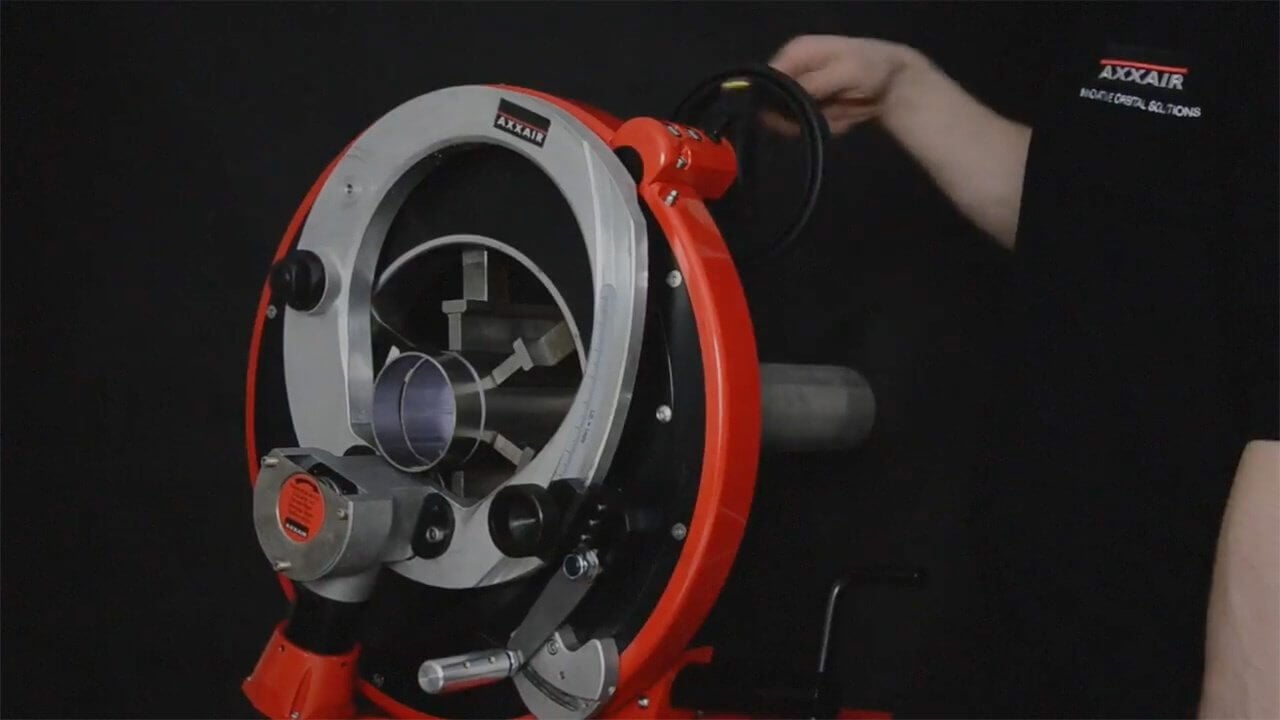

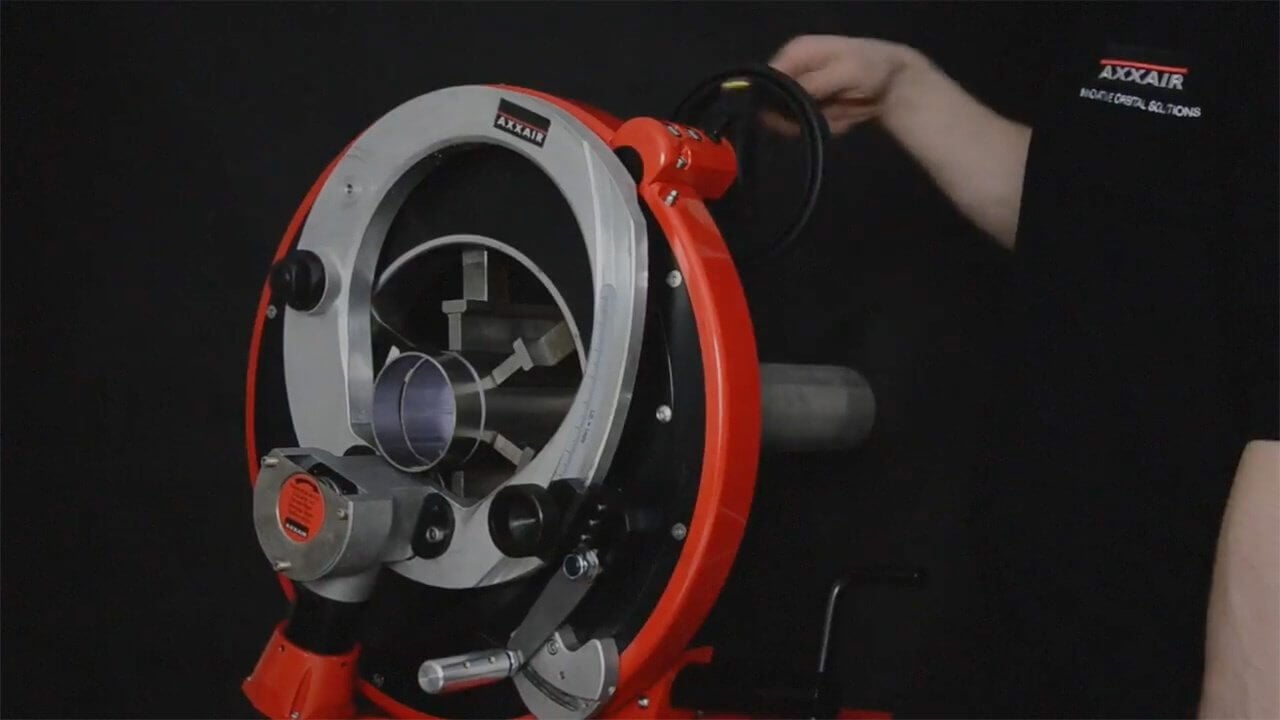

Motorisation interchangeable

DécouvrirMachine de dressage du tube sans bavure

DécouvrirConcept unique et breveté AXXAIR

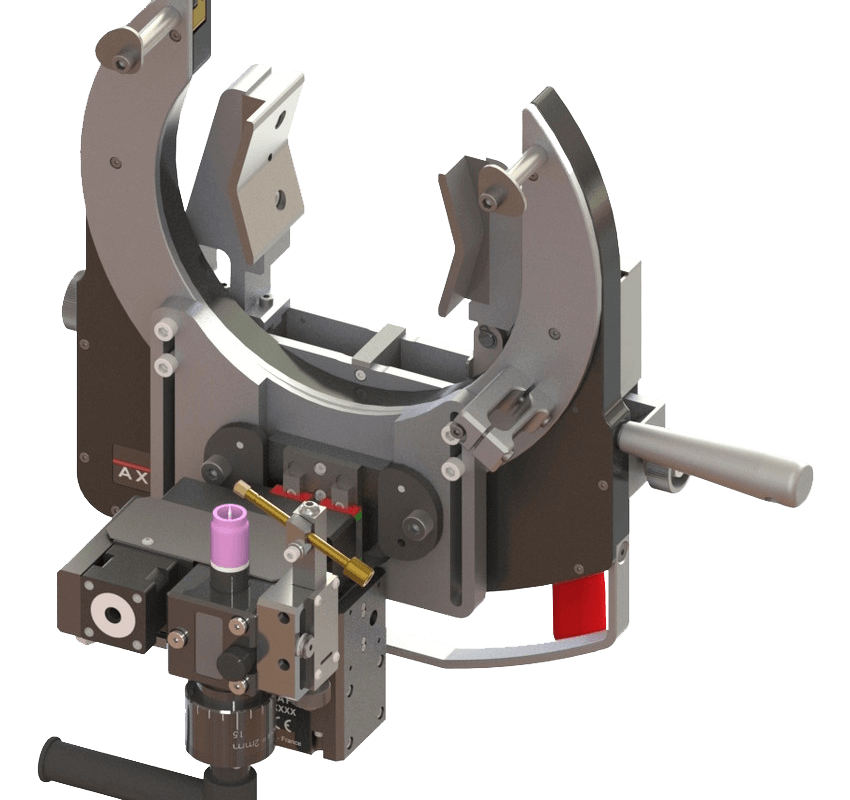

DécouvrirLe tube est fixe, l'électrode tourne autour du tube.

Découvrir

Prototypes, conception industrielle, ingénierie industrielle , production, machines spéciales: depuis les origines de notre société, notre service Recherche et Développement a toujours été une composante essentielle de notre développement.

Propriétaire des brevets liés à nos machines orbitales de process industriels du tube, AXXAIR explore constamment de nouvelles idées liées à la coupe, au chanfrein ou à la soudure orbitale.

En savoir plusT.I.A. souhaitait développer davantage son activité pour des applications tubes fins INOX jusqu’à 2 mm d’épaisseur et ainsi remporter des projets encore plus importants dans l’industrie agro-alimentaire où le soudage orbital devient prédominant.

Lire l'étude de cas

La satisfaction de nos clients après l’acquisition de nos équipements étant un facteur crucial chez AXXAIR, nous veillons à leur accompagnement.

Pour cela, nous proposons à nos clients, distributeurs ou partenaires qui utilisent du matériel AXXAIR des formations afin...

Lire la suite

Aujourd’hui nous vivons le passage à la Quatrième Révolution Industrielle : Industrie 4.0.

Celle-ci nous fait passer de la Troisième Révolution, celle de l’automatisation et des commandes numériques, à l’ère de l‘acquisition de données et le contrôle à distance de...

Lire la suite

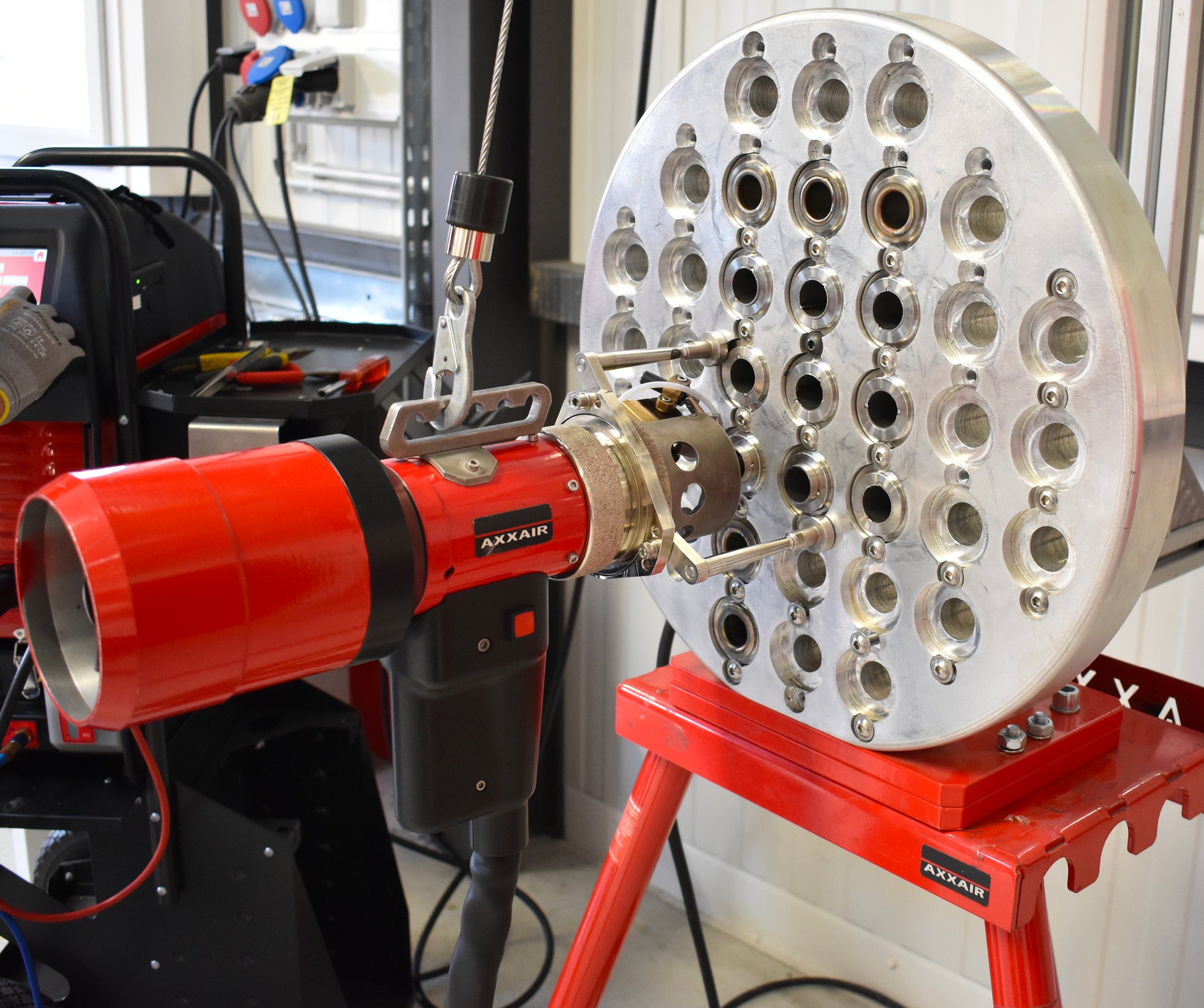

Le soudage orbital des jonctions Tube sur Plaque peut être effectué en TIG manuel ou en TIG orbital. La soudure orbitale permet un gain de temps et une haute qualité de soudage. Les soudures sont documentées afin d’assurer une traçabilité optimale du process de soudage.

Lire la suite

On ne le répètera sans doute jamais assez, la préparation des tubes est essentielle afin d’obtenir une soudure de qualité. Le soudage Tube sur Plaque ne faisant pas exception, il est donc très important de ne pas négliger cette étape.

Lire la suite