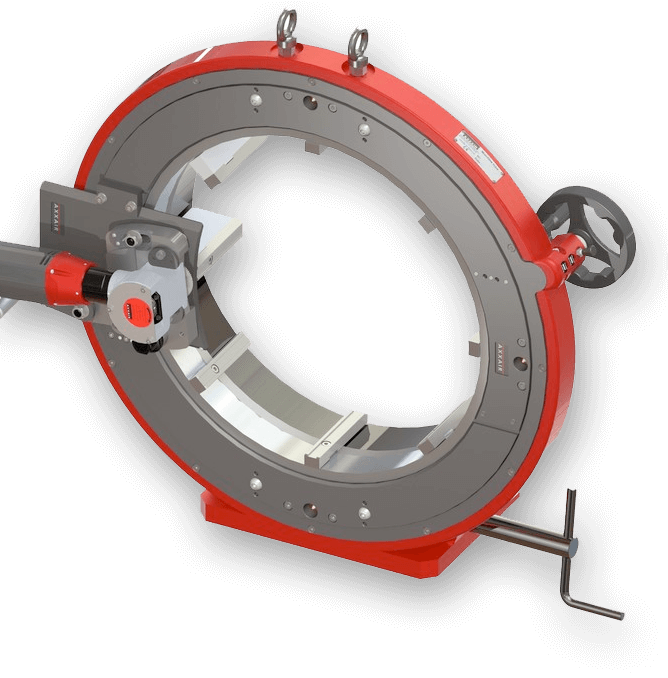

AXXAIR machine frames (with the exception of the CC80 and the CC121 ECO) can be quickly and easily converted into machines for orbital beveling and welding.

Cutting without deforming the tube thanks to concentric clamping collets. Ideal for thin-walled stainless steel tubes and pipes. A cut with perpendicularity < 0.25 mm and excellent, burr-free surface conditions.

AXXAIR machines are easy to move around, which makes them suitable for the use on a worksite as well as in a workshop.

Quick installation of the motor onto the machine frame. Facilitates securing the machine on site (protective plastic casing for the motor included in the delivery).

A standard feature: let turn the motor around the pipe with gear reduction. Avoid wasted efforts and difficult working positions. Ensures an even advance of the tool, which increases blade lifetime and improves the quality of the cut.

AXXAIR's concentric clamping system with 3 to 16 STAINLESS STEEL jaws offers the largest range of diameter capacity per model. Minimised distance from clamping jaw to cutting blade: 15 mm with the basic jaws, 2 mm with additional jaws (depending on the model). This gives you 16 points of contact to ensure a precise cut without tube deformation.

A 304L stainless steel tube of 88.9X 2 mm can be cut in 20 seconds. Easy and direct adjustment of diameter.