The amount of metal shavings caused during the creation of an orbital bevel is drastically reduced by only requiring a single rotation around the pipe. The shaving removal capacity of the carbide tips responds perfectly to this application (unlike the HSS tool). Please do not hesitate to contact us regarding large diameters and special fabrications.

Create a bevel 10 times faster than with a HSS tool!

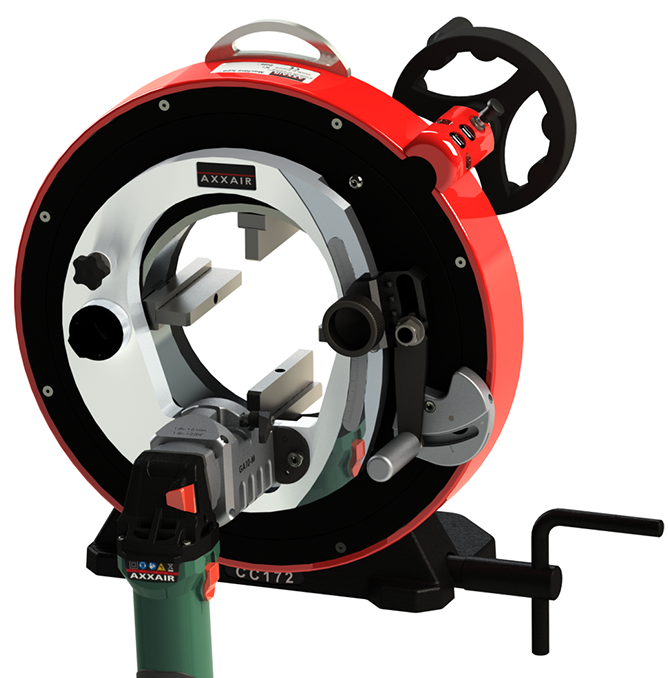

A device for tracking the out-of-roundness of tubes permits an ideal preparation of your pipes before welding

Thanks to the AXXAIR carbide process, creating a bevel causes virtually no vibrations which makes it suitable for the use on light machines. The bevel is formed during a single, fast rotation of the motor around the tube. Set up, adjustment and bevel are simple and done quickly. Each machine can process a large range of diameters without requiring specific clamping jaws.