-

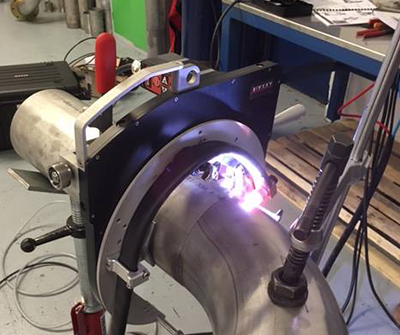

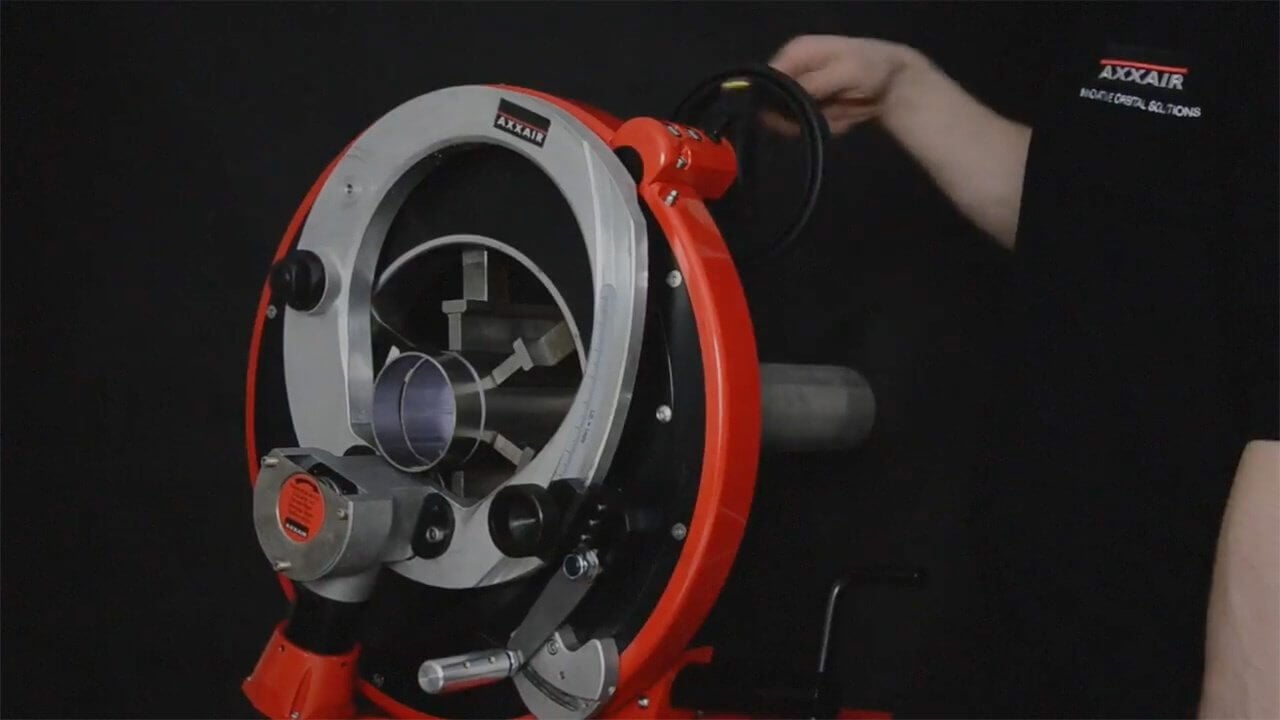

Innovative Orbital Welding

& Cutting solutions

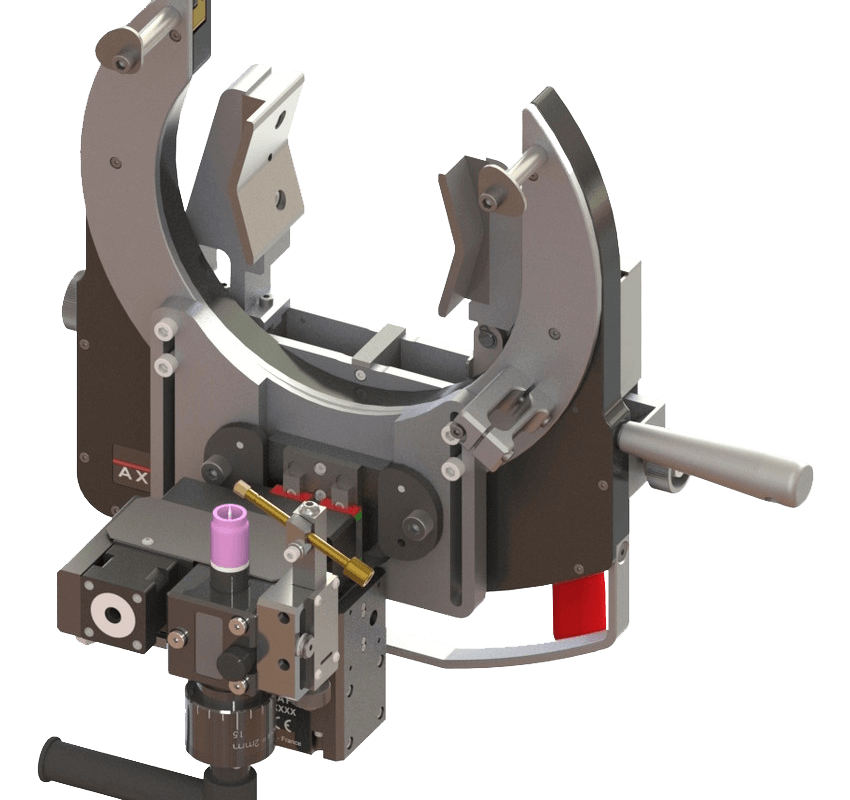

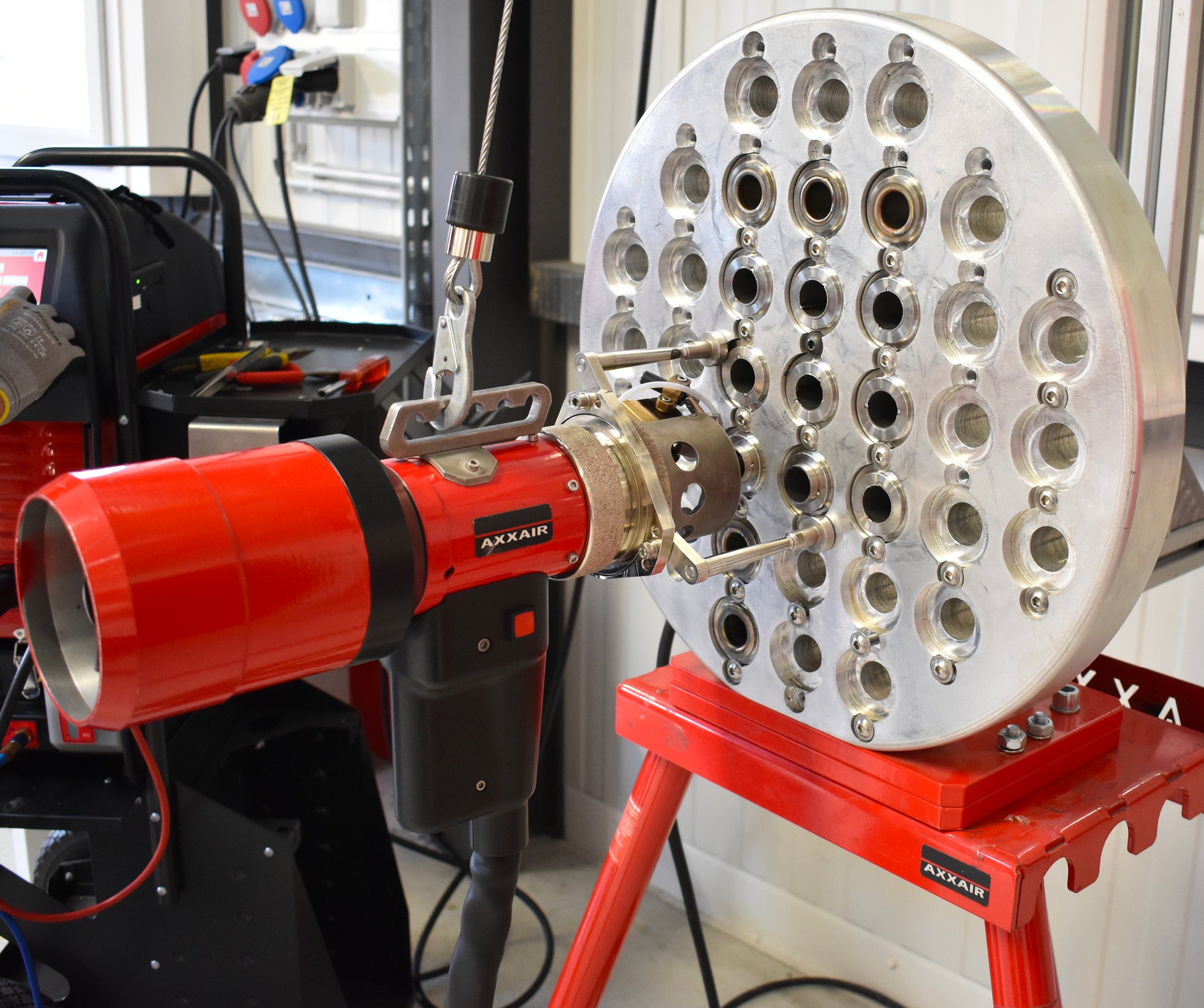

VIEW PRODUCTSPrecision machinery for tube and pipe fabrication.

Wide range of orbital systems made for high purity piping, clean rooms, and sanitary piping fabrication for use on job sites and in the pipe shop.