We use simple and easy-to-use standard parts for all our orbital welding heads. This is ideal for those taking their first steps in the world of orbital welding.

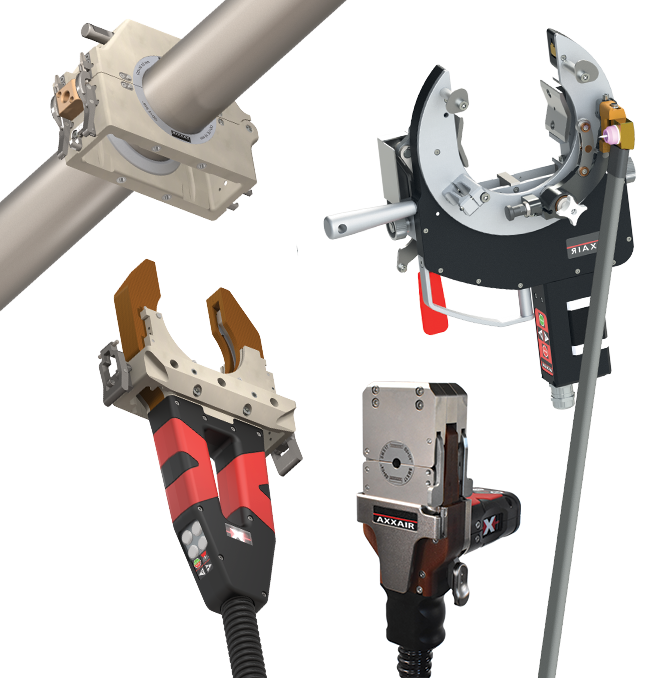

Our open orbital welding heads all feature a device for tracking the tube ovality and are available air and water-cooled.

AXXAIR's SAXX welding power sources are easy to set up and operate. You will be able to perform high-quality orbital welds in no time thanks to its user-friendly interface.

Great to use for sanitary piping, our orbital welding equipment, and tube cutting machines guarantee high-quality, clean, and repeatable results allowing you to meet ASME BPE standards (standard for American Society of Mechanical Engineers - Bioprocessing Equipment). As long as all parameters - including the preparation of the tube - remain the same, you will receive the same level of quality, weld after weld.

View our orbital welding solutions for tube:

View our orbital welding solutions for pipe:

We offer several orbital welding power supplies. The choice of the model depends on the intended use, the tubes that are to be welded and the frequency of utilization. We offer power sources with a maximum current of 300A.

Our power supplies are specifically designed for our orbital welding heads and machines which all respond to the high standards of industrial sectors such as pharmaceutical, food processing, aerospace, semiconductors, petrochemicals, and solar - amongst others of course.

Because the torch is moving around the tube, you can easily manage larger diameters without geometric distortion. Each machine covers a wide range of diameters.

AXXAIR also designs and manufactures orbital weld heads for tube and pipe.