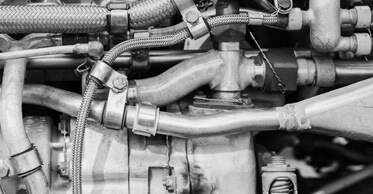

Tubes are a means of transportation in countless industrial sectors. They all have the property of conveying hazardous or delicate fluids. These fluids thus call for quality installations.

Constructing a tubular circuit involves connecting straight tubes with elbows, T-pieces, flanges, and valves among other components. In most cases, the assembly is welded. However, it can also be done by crimping or sleeving. Nevertheless, welding the joints normally offers at least equivalent, if not superior, characteristics over the material making up the tubes themselves. They are therefore nowadays considered a preferred solution. Different types of welding can be applied depending on the use and above all depending on the wall thicknesses of the tubes and the characteristics of the materials to be welded: steel, stainless steel, titanium, austenite steel...

The most frequently used welding process for stainless steel is TIG (Tungsten Inert Gas) welding as it allows for perfect control of the weld pool and is therefore highly suitable for precision welding. AXXAIR has designed and built the best Orbital TIG welding machines and power supplies for precision pipe and tube welding.

Junction points are virtually the only places in the installation where problems such as leaks, microscopic cracks, corrosion, and mechanical brittleness can occur. Depending on the fluid conveyed and the characteristics of the installation (pressure in particular), the junction points and the welds must be carefully checked during production and in the traceability of welding parameters.

Pipefitting involves creating tubular circuits to convey, process, pump and filter fluids or gas required by the production chains of:

Ever since 1997, AXXAIR has been offering orbital system solutions for high-quality tube preparation and orbital cutting as well as machines for perfectly squaring thin tubes with wall thicknesses of up to 3 mm. Our product range also includes machines for beveling tubes of larger wall thicknesses to ensure that you can conduct controlled, high-quality welds.

AXXAIR supports its customers throughout the global process of orbital cutting, squaring, beveling, and welding in over 60 countries worldwide.

We are focused on providing high-quality service in this process while always putting our customers first. This starts by determining the welding parameters and analyzing the necessary preparation during the pre-sale phase. We then train the welders and welding machine operators on our orbital and TIG welding machines and power supplies to ensure that our users can handle every type of application they might be confronted with later on their own.

When a weld is created automatically with one of our orbital TIG welding machines, the machine is capable of logging the real welding parameters at any given moment and can therefore document each weld precisely. Needless to say, that skill is still required to correctly set up the machine and adjust the welding parameters but once it has been calibrated correctly, the machine can infinitely repeat welds of very high quality. The operator can therefore use his knowledge to control the welding process.

The aerospace industry uses very thin wall alloys and titanium tubes, mainly for cooling systems, jet engines, and hydraulic lines. After the tubes have been cut, they need to be squared in order for them to have a burr-free surface and be suited for orbital welding. The welding is done with full gas protection in a closed chamber which subsequently makes the use of a closed head mandatory.

The manufacturing of semiconductors requires ultra-clean installations of high-purity piping lines to transport compressed air, pure gases, and pure water. Leaks or possible retention zones are hence intolerable. In order to bypass such problems, the tubes need to be squared prior to being welded. X-ray inspection of 100% of the welds and orbital welding is often made in a cleanroom environment.

The food processing industry uses stainless steel tubing and thin pipe (usually up to SCH10 and SCH40). For these tubes, it is often sufficient to execute an orbital cut before they are welded together. In this industrial sector, external discoloration of the tube is tolerated which is why it is possible to use both open and closed welding heads. Weld testing is carried out by sampling. More and more food, dairy, & beverage processing fabrication projects in the United States must fit with ASME BPE standards.

The industrial sectors for chemicals and petrochemicals work with pipes (usually SCH10 and above) often made of stainless steel or other refractory materials with a high corrosion resistance but also of carbon steel. The pipes are cut and beveled before being welded with a manual or orbital welding process. The multi-pass weld is carried out with AVC (Arc Voltage Control) and Oscillation of the welding torch on the AXXAIR orbital welder.

The bioprocessing equipment manufacturers in the pharmaceutical industry require precise cuts and quality welds to avoid any bacterial contamination: the welds are often subjected to 100% x-ray testing (depending on the country). These high-purity sectors use sanitary stainless steel tubing (.065 and .083" wall). The tube needs to be squared/faced after being cut in order to get a high-quality and burr-free surface finish before orbital welding.