Orbitally welding tubes to tube sheets can be done using either manual TIG or orbital TIG. Orbital welding saves time and produces high quality welds. The welds are documented to ensure optimal traceability of the welding process.

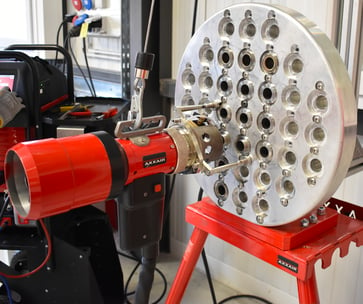

At AXXAIR the orbital tube-to-tube-sheet welding process is carried out with the SATP-80X machine, which features the following functions:

- Inclined electrode

- Water cooled heads: Cooling is a key function when using these heads because, as is often the case with the application on the previous page, the whole exchanger is heated to avoid cold cracking. It is important to cool down the head, especially as the operating cycles are often close to 100%.

- If wire is needed, it is important that the wire spool is mounted firmly on the front rotating part to avoid twisting the wire, which would cause alignment drifts when entering the weld bath.

- It is possible to start the cycle from the handle: this avoids wasting time as the station is often situated at a distance.

ATTENTION:

We would first like to emphasize that these tube-to-tube-sheet applications can be complex and require knowledge of the preparation and geometry of the tube assembly.

AXXAIR provides machines that are capable of welding these configurations, and we can share our experience with you, but AXXAIR is not responsible for the welds and welding results. It is the responsibility of the customer to decide, according to the specifications of the heat exchangers, how to prepare and place the tubes in the tube sheets.

Needless to say, this decision has a direct impact on the outcome of the weld.

All weldable materials can be used in tube-to-tube applications. However, the dimensions of the tubes used in these applications are limited.

The diameters generally range from 12.7 to 101.6 mm (5 to 40”) for thicknesses between 0.5 and 5 mm (1/5 to 2”). The majority of applications work with diameters between 19.05 mm and 38.1 mm (3/4 and 1.5'') and thicknesses between 1.65 and 3.4 mm (2/3 and 1.3”).

Almost all industries use heat exchangers, but they primarily made their way into the chemical, petrochemical and energy industries.

.jpg?width=416&name=Tube%20to%20tube%20sheet%20(3).jpg)

General Characteristics

The equipment used also differs slightly depending on the type of application and the level of automation required:

- The standard equipment without filler wire consists of a suitable orbital power supply and a tube-to-tube welding head with a gas chamber for gas protection, which is particularly necessary when welding titanium tubes.

- The standard equipment with wire is an orbital power supply capable of feeding a wire and a tube-to-tube welding head with wire. This equipment is suitable for single pass applications.

- The standard equipment with wire includes an orbital welding power supply capable of feeding wire and an adapted tube sheet welding head with wire. This equipment is fit for single pass applications.

It can be used for double pass applications but sometimes manual adjustment of the electrode between passes is required.

- More complex heads can be used that feature automatic lifting of the electrode between passes that allows you to make two passes without stopping the machine. AXXAIR does not carry these types of heads at this time.

- The more complex heads are equipped with AVC/OSC capability to suit very special needs. AXXAIR does not provide these solutions on their welding heads.

Please note: Centering tools not manufactured by AXXAIR must be adapted to the position of the tube in the tube sheet.

The contact area between the tube and the tube sheet must be perfectly clean and free of grease or oil or other substances as this would create bubbles in the weld bead which is not permissible.

The tubes must NOT be expanded in the tube sheet before welding as the gases emitted during the weld would not be able to evacuate and would cause an "explosion" at the end of the welding process. Automatic welding would then be impossible.

Watch our video dedicated to the machine SATP80X :