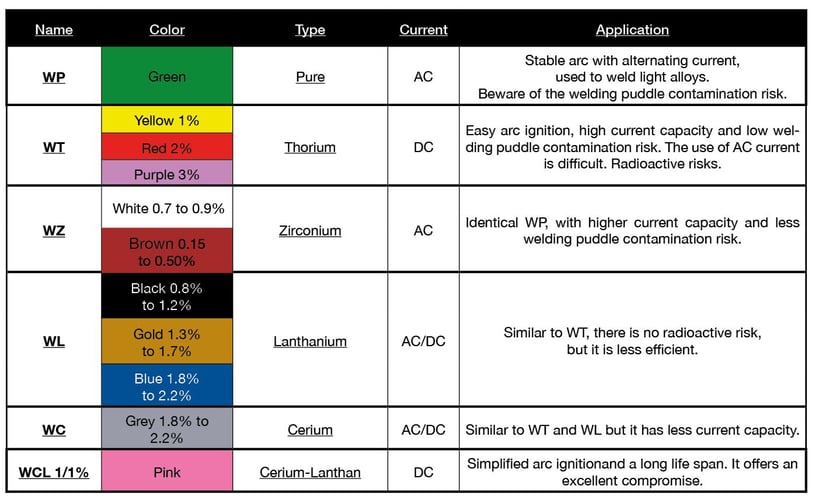

Tungsten electrodes are classified according to their chemical composition. For more information please refer to the standard ANSI/AWS A5.12-92.An electrode is always made of tungsten, either pure or containing different alloys or oxides. Below a list of the different types of tungsten electrodes used in orbital TIG / GTAW welding. This will help you choose the right tungsten when it comes to TIG welding.

Pure Tungsten (green):

This kind of electrode with limited current density, is mostly used with alternative current for welding aluminium alloys - as the small ball that is formed at the extremity of the electrode is very clean and permits to the arc to stay stable. Pure tungsten electrodes are not recommended for welding under direct current as they offer poor results regarding the strike and the stability of the arc. Another inconvenience is that this type of electrode might create tungsten inclusions.

ADVANTAGE

The main advantage of this kind of electrode is the low purchase price.

Zirconium-Tungsten (white 0.7% to 0.9% and brown 0.15 to 0.50%):

This is the most common electrode reference for aluminium welding under alternative current (AC).

ADVANTAGES

Easy striking and arc stability, high admitted current density, reduction of the risk in terms of tungsten inclusions.

Thorium-Tungsten (yellow 1%, red 2% and purple 3%):

This is certainly the kind of electrode the best known and the most used in the world of manual GTAW / TIG welding. They have a higher admitted current density, and a better emissivity of the electrons. They limit the temperature of the electrode, thus avoiding the risk of weld contamination by tungsten inclusions (non miscible element).Thorium-tungsten electrodes are mostly used under direct current. If used under alternative current, maintaining the small ball at the extremity of the electrode would be very difficult, which explains why they are rarely used under alternative current.

INCONVENIENCE

The thorium tungsten has a very low level of radioactive oxides, therefore it is used less and less - for hygiene, and for security reasons. You have to protect yourself during the sharpening of the electrode.

Cerium-Tungsten (grey 1.8% to 2.2%):

Initially introduced in the US at the beginning of the eighties, this type of electrode takes market shares on the thorium electrodes as they do not contain radioactive oxides. They can admit the same density of current as the pure tungsten electrodes, have a good lifespan, and provoke a good strike of the arc and a comparable arc stability.

ADVANTAGE

This is a very polyvalent solution as you can apply them with direct or alternative current, and they are often used for all automated TIG welding applications.

Lanthanium-Tungsten (black 0.8% to 1.2%, gold 1.3% to 1.7% and blue 1.8% to 2.2%):

This tungsten is very similar to the Thorium-Tungsten.

ADVANTAGE

The Lanthanium-Tungsten is very versatile and works with both, DC (direct current) and AC (alternating current) and is widely used for all automated TIG / GTAW welding applications. It does not involve any radioactive risk.

INCONVENIENCE

It is less efficient than the Thorium-Tungsten.

Cerium-Lanthan-Tungsten (pink)

Nowadays welders prefer to use cerium or lanthanum electrodes, or a mixture of both, which do not present any radioactive risk. Moreover, they are just as effective as thorium tungsten.

ADVANTAGE

The arc ignition is simplified and the tungsten’s life span is long. This Cerium-Lanthanium-Tungsten offers an excellent compromise!

Tungsten classification:

Download our handbook and learn out more about how to choose the perfect electrode for orbital TIG welding!