The choice of the right tungsten electrodes in GTAW, or TIG welding, is of the utmost importance. Concerning the parameters to be considered when you do TIG orbital welding, the following three parameters will help you to make the right choice.

Criterion 1: Choosing the right tungsten type

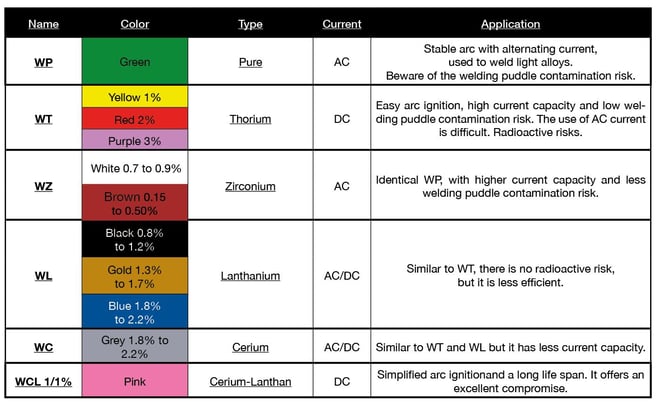

Different types of tungsten electrodes are available on the market:

The choice will be made according to the type of welding current: alternating or direct. Alternating current (AC) is mainly used to weld aluminum. The polarity between the tube (mass) and the electrode is alternately reversed, so that the electrons run back and forth between the tube and the electrode, which has the effect of breaking the aluminum oxide layer that causes resistance and prevents fusion.

Direct current (DC) is the most popular, all our welding power supplies are equipped with it. The polarity is set, usually the tube (mass) is positively charged and the electrode is negatively charged. Electrons are attracted by the tube and move from the electrode to the tube. This process is used on most metals to be welded.

Some machines are equipped with AC and DC so they can perform both. The tungsten electrode type will be selected according to the current used.

Criterion 2: Diameter, length, selection of the electrode.

The size of the tunsgten electrode primarily depends on the equipment used to weld. A manual torch will have a length of 100 mm or 200 mm and will be cut and sharpened as it goes along.

Here are some tungsten electrode sizes in relation to our different machines:

Closed (SATFX) and Microfit (SXMF) welding heads: electrode size depends on the diameter of the tube to be welded and the type of welding head.

For manual torches (SATM), open welding heads (SATO) and prefab machines (SX): always 50mm with a long diffuser and 22mm with a short diffuser.

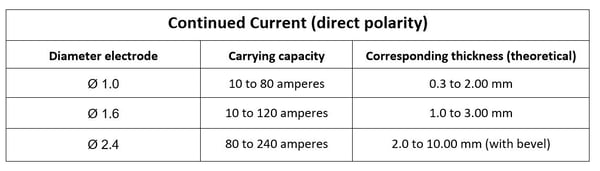

The diameter depends on the welding current.

With a current of up to 100 amperes, you can weld with a diameter of 1.6 mm: everything above that constitutes a risk of damaging the electrode and with that tungsten inclusions in the weld bath, which is a major deficiency.

For 80 amperes and up, you can use an electrode with the diameter of 2.4 mm: if you use that electrode on currents of less than 80 amperes, the arc will not be stable because it has “too much room” and is not channeled.

For further information, please refer to the standard ISO 6848.

The standard lengths vary between 100 mm and 200 mm, the electrode diameters reach from 0,25 mm to 10 mm (0,01 to 0,25 inches).

AXXAIR offers pre-sharpened and pre-cut tungsten electrodes with lengths of 50 mm for open welding heads and lengths of 15 mm to 59 mm for closed welding heads. Additionally, we are working with three different diameters: 1 mm for the closed Microfit heads (SMFX), 1.6 mm and 2.4 mm for open welding heads (SATO), closed heads (SATF), prefab machines (SX) and tube-to-tubesheet welding (SATP).

Diameter electrode/carrying capacity

Range of currents per electrode diameter:

As you can see, the choice of tungsten electrode depends on the base material, the type of current used as well as on the welding current.

For more information, please refer to the standard NF EN 26848 or ANSI/AWS A5.12-92.

Criterion 3: The geometry and the surface condition of the electrodes

The purchase price sometimes might determinate the choice of the tungsten electrodes. This is an important parameter, sometimes ignored, for the functioning of the orbital TIG process, in order to ensure repeatable welds.

Users of automated TIG systems normally use:

- Electrodes sharpened in the direction of the axis: the grooves must be longitudinal to avoid arc mobility and the potential detachment of tungsten particles. Sharpening will ideally be carried out parallel to the longitudinal axis of the electrode. The grinding must also result in a good surface finish with a maximum roughness of RA 0.8.

- Cleaned electrodes help avoid surface impurities. According to the standard ISO 6848: "Electrode surfaces must be free of impurities, unwanted coatings, inclusion of foreign matters, splinters, cracks, flaking and other defects. The electrode body must be free of foreign body inclusions or any other defects that would adversely affect the use of the electrode". If the electrode is oxidized (darkened or bluish in color), proper welding is no longer guaranteed. It is then said to be polluted and, in this case, it may pollute the weld bath. It becomes contaminated for example if a weld is started without gas, or with an impure gas, if a projection of the weld bath sticks, or if it has been touched during welding. There is then nothing else to do but to change the electrode, sharpening it would be useless.

>> types of electrodes used in orbital TIG welding

These elaborated conditions will provide you with a better conductivity between the electrode and the electrode tongs and a better transfer of the electric arc.

Are you interested in learning more about orbital welding technologies and how to choose your electrode ?

Do not hesitate to download our handbook