The industry has been evolving constantly in recent years and has undergone several industrial revolutions until it arrived at the current industry, Industry 4.0. What are the different industries? What is Industry 4.0? How does it involve AXXAIR? Find the answers to all these questions in this article!

From Industry 1.0 to Industry 4.0

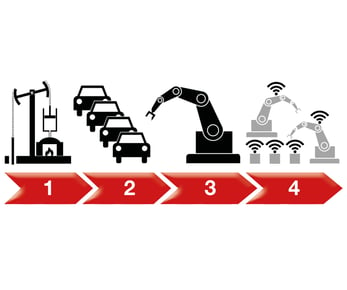

Before we introduce Industry 4.0, let's start by briefly reviewing what the industry is all about. Industry is the set of economic activities that produce goods by processing and using raw materials. It has undergone several major industrial revolutions between 1700 and today, as illustrated in the diagram below: 1st industry (18th century): Mechanization, steam power, hydraulic power.

1st industry (18th century): Mechanization, steam power, hydraulic power.

2nd industry: Mass production, assembly lines, electrical energy.

3rd industry (20th century): IT and automation.

4th industry (21st century): Cyber Physical systems.

The new revolution is based on the intelligent factory, based on the interconnection of machines and systems within the production sites but also between them and outside. In a way, it is the digitalization of the factory. The concept of this latest revolution was first introduced at the Hannover Fair (in Germany) in 2011 and was then presented in a report describing the diagram by a transdisciplinary working group at the Hannover Fair in 2013.

Industry 4.0: the smart factory

Industry 4.0, also known as connected factory, smart factory or industry of the future, corresponds to a new way of structuring the means of production. It organizes production processes driven by innovations related to the Internet of Things and digital technologies: artificial intelligence, augmented reality, robotics, 3D printing, cloud, additive manufacturing - all in order to be able to process data.

This fourth industrial revolution refers to the transformation of production systems by the introduction of new technologies.

The purpose of this industrial revolution is the creation of smart factories that can easily adapt to production processes.

This factory of the future, "factory 4.0", takes the form of an innovative, fully digitalized factory, oriented towards new technologies, while being environmentally and socially responsible. It not only affects the economic aspect, but also has social, political and environmental impacts related to this new way of producing.

Large companies such as Schneider Electric, Siemens, Airbus, Bosch, and others are very involved in the development of the factory 4.0. Many startups exploit new technologies for the enhancement and optimization of their prospective industry.

Even if more and more companies and large enterprises are adopting the industry 4.0, it is not only a label but rather a developed concept, which does not respond to any standard, but is generalized because of its added value within industrial companies.

AXXAIR and the industry 4.0

AXXAIR is constantly striving to improve the operator experience. This generally applies to all the machines of our product range: cutting, squaring, beveling and orbital welding. Let's have a closer look at our SAXX orbital welding power supplies. The connectivity of our SAXX power supplies now offers new features to adapt to the needs of our customers.

From the very beginning of the launch of our power supply, the Wifi feature was available in order to use the "Remote HMI" application and operate the power supply from a smartphone, computer or tablet. This Wifi option, which is suggested when purchasing the power supply, also makes it possible to send and retrieve data from the SAXX thanks to the given access to the USB key of the power supply.

As of now, this remote access is also possible with an Ethernet network cable. Our SAXX power supplies are nom equipped with an Ethernet socket at the back of the power supply as standard, which enables them to be connected to a computer network.

Access to the contents of the USB key allows to monitor alarms, retrieve data log files (as you go or every night for example) and to exchange and share configurations and programs from one SAXX power supply with other SAXX power supplies.

The new versions of the orbital power source SAXX (the 200, 210 and 300 range models), will also benefit from a new and improved Wifi module as an optional feature. It allows for a better quality and stability of the Wifi communication and the operating distance of the wifi can be up to 100 m depending on the environment.

Additionally, Weld Report - our very own data reporting software developed for AXXAIR welding power supplies - is part of this approach as it supports remote and connected data collection and processing.

Our slogan "Innovative Orbital Solutions" is part of AXXAIR's DNA: the optimization and continuous improvement of our products is what drives us.

This is precisely the reason why, for more than 20 years, we have been looking for solutions to facilitate the daily life of the operators of our machines and desire to strive for maximum connectivity of our equipment. AXXAIR's goal is to sustain existing markets but also to support our customers so that they can use our equipment to its full potential while enabling them to achieve their manufacturing objectives.

Optimizing the production chain but also the quality control means in place ensure the reliability of the monitoring and the smoothness of the customer's control process.

As you will have understood, the digitalization of the factory and its production are starting to take a more and more important place in the industrial world. This Industry 4.0 introduces connectivity and digitalization solutions to help manufacturers optimize their production process.