Let us return to the question of the bevel, which will reduce the thickness of the tube in order to allow welding. Generally speaking, a tube with a wall thickness of more than 3 mm cannot be welded with only one layer in TIG welding.

TIG welding is a Tungsten Inert Gas process: Tungsten designs the electrode and Inert Gas the plasmagenic gas used for shielding.

In order to weld thicker pipe, a bevel must be carried out at one edge of the tube to be welded to another pipe / bend / reduction / connections (T,Y), which also have to be bevelled.

The bevelling systems often are of “manual” type.

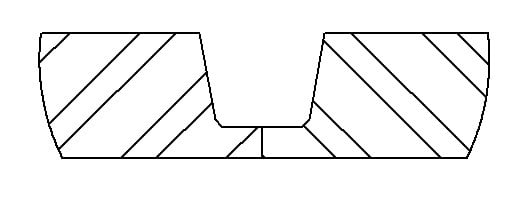

J or Tulip bevel

The other technical way of bevelling is called “bevel for orbital welding” and this one is different compared to the J or tulip bevel.

- The shape of the bevel used for orbital welding is different as it has a flat land at the edge of the J or tulip bevel with a thickness of 1,8 to 2 mm. This land will facilitate smoothing and straightening.

- The act of smoothing and straightening consists of realizing a plane reference enabling the machining of the other faces. In this way a finer thickness will be created in the inner side of a tube. Example: A thickness of 8 mm before bevelling and only 2 mm remaining for the land.

- The two lands of the workpieces with a land thickness of 2 mm will be in contact. Only a simple fusion of the lands will be necessary and afterwards the bevel can be filled with filler wire using orbital welding technology.

V Bevel

On the other hand if you choose a “V”-bevel, you will plane the two pieces to be welded in this form. In this shaved groove in V-form the welder looks for a welding penetration. In order to do so he creates a weld puddle on the inner part of this “V” in order to fill the material that has been removed.

How can I choose between a “V or a “J” bevel?

The “V” bevel is used for manual welding. Whereas, the orbital welding processes more commonly use the “J” bevel preparation.

In order to make a “V” or a “J” bevel you can find different shapes of tool bit with a “V” or “J” shape.

Making a “J” bevel for manual welding is of no interest, as the angle is too large for a manual procedure. The choice of the bevel essentially depends on the welding process.

Advantages of an orbital bevelling machine

An orbital bevelling machine has certain advantages:

- the execution of the bevel is very quick, with only one pass around the pipe - a clean bevel without any burr.

- The carbide tool does not modify the nature of the material.

- The rejection rate is very low thanks to the precision of the tool which makes high quality end preparation.

- The bevel angles in “V” shape can be carried out in three different degrees: 30, 37,5 and 45°.

The orbital bevelling technology allows you to choose between two beveling preparations which have been successful.

The orbital bevelling is part of the global process: from orbital cutting to final welding. Interested? Here you can download our handbook on orbital TIG welding free of charge!